biotech & regenerative manufacturing

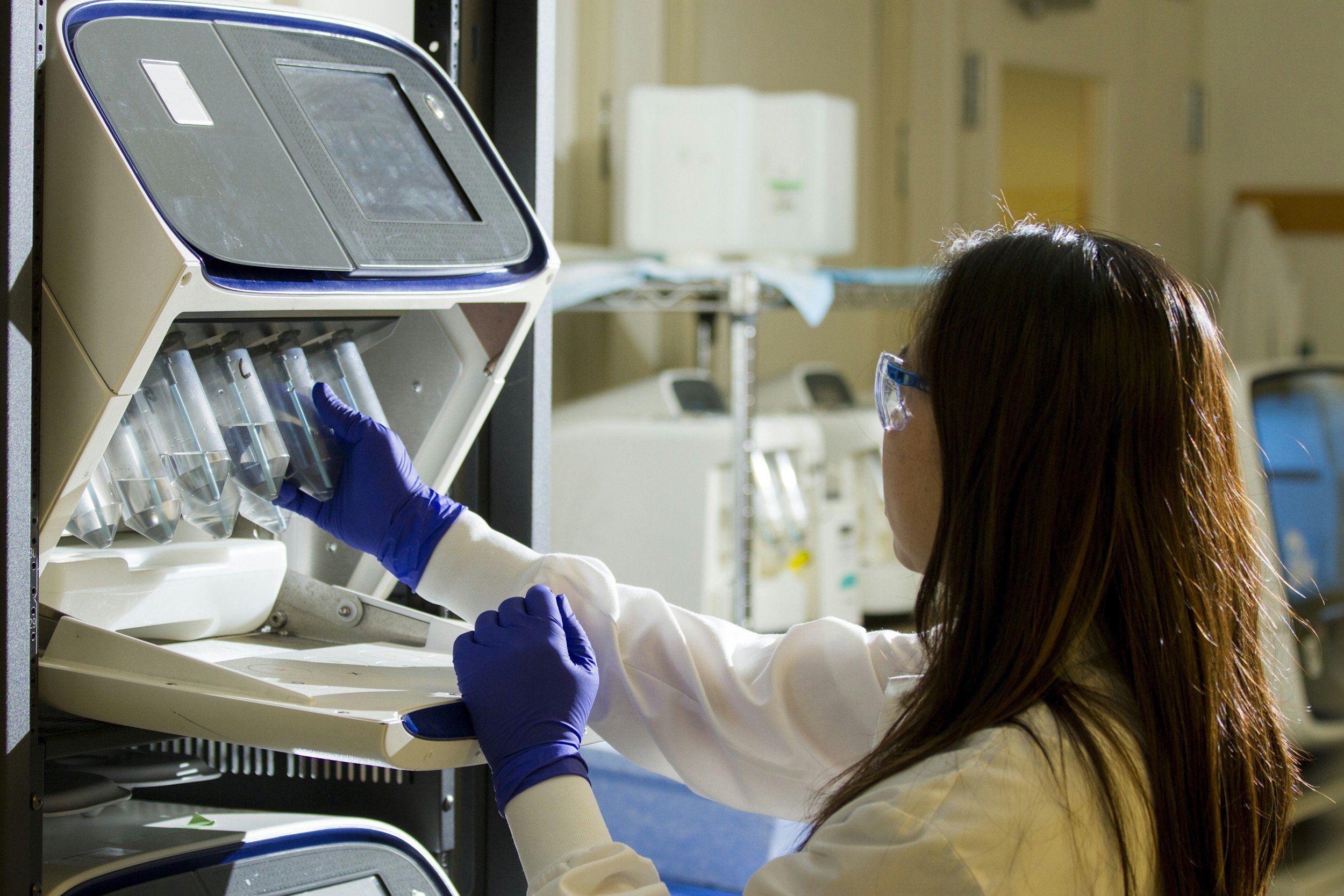

Biotechnology and regenerative manufacturing are transforming the future of medicine, sustainability, and advanced manufacturing. these intersecting fields are creating new possibilities for drug development, tissue engineering, and beyond.

What Is Biotech Manufacturing?

Biotech manufacturing, or biomanufacturing, harnesses living cells, enzymes, or entire biological systems to produce therapies, vaccines, diagnostic reagents, and more. Unlike traditional pharmaceutical manufacturing—which relies on chemical synthesis—biomanufacturing produces complex molecules like antibodies, hormones, and other biologics using sophisticated biological processes. These products include:

Monoclonal antibodies (mAbs)

Vaccines

Viral vectors

Recombinant proteins

Cell and gene therapies

Growth factors

Blood products

https://www.susupport.com/knowledge/biopharmaceutical-products/vaccines/biomanufacturing-process-steps-challenges-manufacturing-biologics

The manufacturing environment for biologics requires extremely high levels of control. Even tiny traces of contamination or process variability can compromise entire batches of finished medicine, making rigorous quality controls and regulatory standards essential.

in new hampshire, the legendary inventor and entrepreneur, dean kamen, has fostered a new initiative in regenerative manufacturing. through biofab USA, a network of partners is bringing advanced production methods to the creation of human tissues. the focus applies research from across america to scale up a new model for an automated and closed system in biotech manufacturing. acting as the bridge between science, regulatory requirements, and the commercial product, the team is supported by federal grants, including funding from the department of defense. the latter seeks to aid veterans and soldiers suffering from injuries.

in Indiana, home to many life science innovators, the bioworks tech hub unites research, academics, and commercial interests to accelerate discoveries in human, animal, and plant bioscience.

what is Regenerative Manufacturing?

Regenerative manufacturing takes biotechnology further by focusing on repairing, replacing, or regenerating human tissues and organs. It combines:

Stem and progenitor cells (the progenitor cell is limited in the number of times it can replicate and can only differentiate into its “target” type) — https://stemcell.ucla.edu/glossary/progenitor-cells

Biomaterials and engineered scaffolds (biocompatible synthetic or natural polymers)

Advanced manufacturing methods, including automation, closed-system cell handling, and 3D bioprinting

Some notable areas of regenerative manufacturing include:

Cell therapies for neurodegenerative, cardiac, or orthopedic diseases

Engineered tissue patches and organoids

Scaffold-based tissue reconstruction

3D-bioprinted vascularized tissues for transplantation

The manufacturing process, however, remains complex and individualized due to the need for strict quality controls, reproducible expansion of living cells, and tailored formulations for each therapy. pmc.ncbi.nlm.nih

what’s coming down the pike?

3d bioprinting: the fabrication of complex, mulit-material tissues brings artificial organs closer to reality.

https://go.zageno.com/blog/2025-trends-in-biotech-and-life-sciences-research

Automation and AI: Robots, AI, and machine learning technologies are increasingly automating everything from cell culture to quality assurance, raising production speed while reducing the risk of contamination.

https://www.startus-insights.com/innovators-guide/top-10-biotech-industry-trends-innovations-in-2021/Standardization and GMP: With the shift from bespoke, small-batch processes to larger-scale clinical manufacturing, regulatory focus on good manufacturing practices (GMP) and standardized raw materials is increasing.

https://www.akadeum.com/blog/gmp-biotech/

https://pmc.ncbi.nlm.nih.gov/articles/PMC6090514/Personalized Manufacturing: Regenerative therapies and biologics are becoming more patient-specific thanks to genomics and precision medicine analytics, improving outcomes while requiring new adaptive manufacturing models.

Sustainability: Biotech and regenerative manufacturing are both tapping sustainable materials and waste-reducing, energy-efficient methods to address environmental challenges.

https://www.kearney.com/service/operations-performance/article/regenerative-manufacturing-unlocking-asean-s-growth-through-design-and-ai

https://go.zageno.com/blog/2025-trends-in-biotech-and-life-sciences-research

The convergence of biotechnology and regenerative manufacturing promises a future where once-impossible therapies—like lab-grown organs, personalized regenerative treatments, and highly targeted biologics—become realities. As these sectors shift toward automation, sustainability, and large-scale production, they’re poised to reshape not just healthcare, but also global manufacturing and environmental stewardship.